Wells and Borings

- Request/Look-up Services

- Wells and Borings Home

- Well Tested? Well Done SE Minnesota

- CEUs

- Construction of Wells and Borings

- Contractors

- Fees

- Laws and Rules

- Licensing

- Minnesota Well Index

- Natural Disasters

- Permits

- Publications

- Resources

- Sealing of Wells and Borings

- Special Construction Areas

- Water Quality and Testing

- Water Information

- Well Disclosure

- Well Partners

Wells Program

Related Topics

- Accredited Laboratories/Well Water Testing

- Clean Water Fund

- Contaminants in Water

- Flooded Wells

- Pesticides

- Water and Health

Environmental Health Division

Protecting Your Well

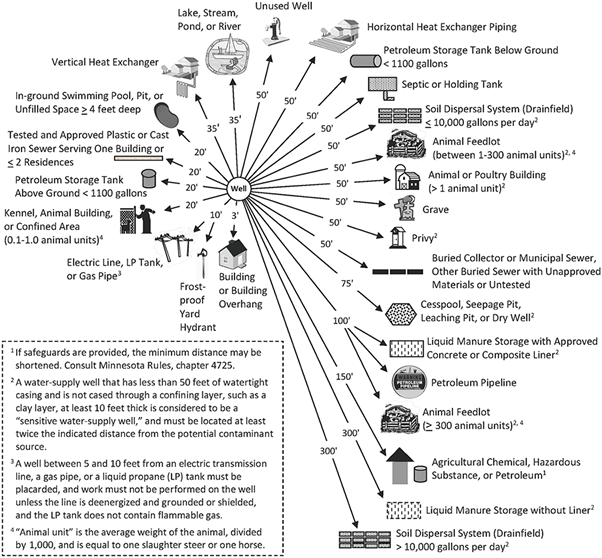

Selected Well Isolation Distance Requirements

(See Minnesota Rules, chapter 4725 for a complete list of requirements.)

This page provides basic information to assist you in protecting your well. A well provides a reliable, safe source of drinking water when the well is properly located, constructed, and maintained. You can ensure the safety of your drinking water by testing the water periodically, keeping potential sources of contamination away from the well, and sealing unused wells.

Casing damage

Be careful not to bump the well while working with trucks, equipment, lawn mowers, or snow plows. Bumping the well can crack the well casing, connections, or the grout seal around the well. Such damage may allow contaminants to enter the well. If a well is located in a high traffic area, protect it by placing three steel posts around it. Place flags or reflectors on protective posts or the well casing to increase the visibility of the well.

Hazardous chemicals

Store agricultural chemicals at least 150 feet away from the well unless the storage area meets the standards of the Minnesota Department of Agriculture. Portable anhydrous ammonia tanks should be at least 50 feet away from the well. Fill bulk or spray tanks at least 150 feet away from the well preferably in a down-slope direction. When filling tanks, avoid the potential for back-siphoning into your well by fixing the nozzle of the fill hose above the tank opening and allowing the water to fall at least twice the diameter of the delivery pipe before entering the tank (air gap).

Location

The diagram below indicates the minimum separation distances required between wells and some common sources of contamination typically found on home or farm sites. A complete listing is found in Minnesota Rules, chapter 4725. Minnesota law requires that these distances must be maintained when constructing a new well; installing potential contaminant sources, such as a fuel storage tank, septic system, or a feedlot; or when constructing new buildings, or adding onto existing structures or facilities.

Click image to enlarge.

Plumbing

Keep plumbing in good repair to maintain watertight connections. Make sure that any faucet that is threaded for a hose has a backflow prevention device. Connections that are not protected may back-siphon contaminants into the water-supply system. Minnesota Department of Labor and Industry regulates plumbing and maintains the Minnesota Plumbing Code.

Septic system

Proper location, design, construction, and maintenance are important. Recommendations for pumping septic tanks are based on the use and size of the system. This information is available from the University of Minnesota-Extension or the Minnesota Pollution Control Agency (MPCA). Do not rely on additives. They may simply dissolve materials and send them to the drainfield. Do not dispose of hazardous materials, such as solvents and oil, in the septic system. MPCA regulates individual and midsize subsurface sewage treatment systems under Minnesota Rules, chapters 7080 and 7081.

Minnesota Pollution Control Agency Resources:

- Healthy septic systems

- Septic system DOs and DON’Ts (wq-wwists6-14) (PDF)

- Subsurface sewage treatment systems

Water quality test

Test your well water for coliform bacteria every other year. Test for nitrate every other year, or more frequently if nitrate previously has been found. The well water should also be tested at least once for arsenic. If the well shows contamination, consult your local county health department, the Minnesota Department of Health (MDH), or a licensed well contractor. Have the well and plumbing system disinfected after work is done on the well or pump. Well water should be tested by a laboratory certified by MDH. For a list of certified laboratories, visit Search for Accredited Laboratories website. You can also look in your local Yellow Pages under “Laboratories-Testing.” Be sure that the laboratory you choose is state certified to perform each test you want.

Additional Resource:

Accredited Labs in Minnesota Accepting Samples from Private Well Owners (PDF)

Well cap or seal

Keep an approved watertight cap or seal securely attached to the well in order to prevent the entry of insects, animals, and other contaminants. Inspect wire connections to the pump.

Well pit

A well pit may serve as a catch basin for contaminated surface water and precipitation. Any well located in a pit should have the casing extended above grade and the pit filled with clean earth. Because of the danger of injury or asphyxiation only a properly trained licensed well contractor or a licensed pump installer should enter a pit.

Well sealing

Unused wells must be properly sealed to prevent direct contamination of groundwater. A well must be sealed by a licensed well contractor or a licensed well sealing contractor.

Additional information about wells and well water can be obtained from a well specialist at the MDH or a delegated well program (for wells located within the jurisdiction of a delegated well program). The requirements of law and rule are found in Minnesota Statutes, chapter 103I, and Minnesota Rules, chapter 4725 (well code).

Print information sheet

Questions

Well Management Section

651-201-4600 or 800-383-9808

health.wells@state.mn.us

Go to > top